MS Metal Supplies Sdn Bhd

MS Metal Supplies Sdn Bhd

MS Metal Supplies Sdn Bhd

MS Metal Supplies Sdn Bhd

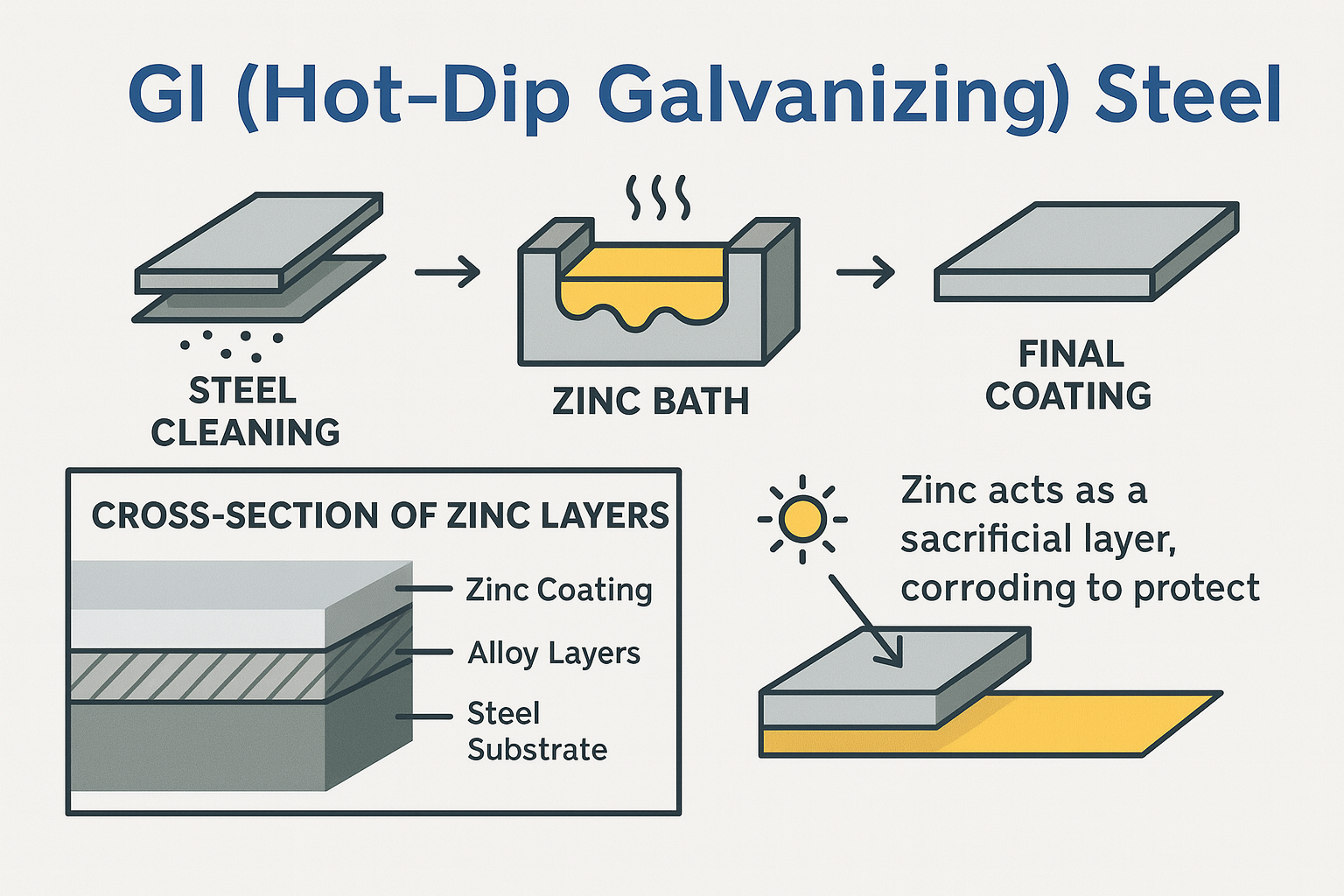

Galvanization is the application of a protective zinc coating over steel or iron to prevent rust. In GI steel, the zinc layer shields the base metal in two ways: it provides a physical barrier and offers sacrificial (cathodic) protection by corroding before the steel does.

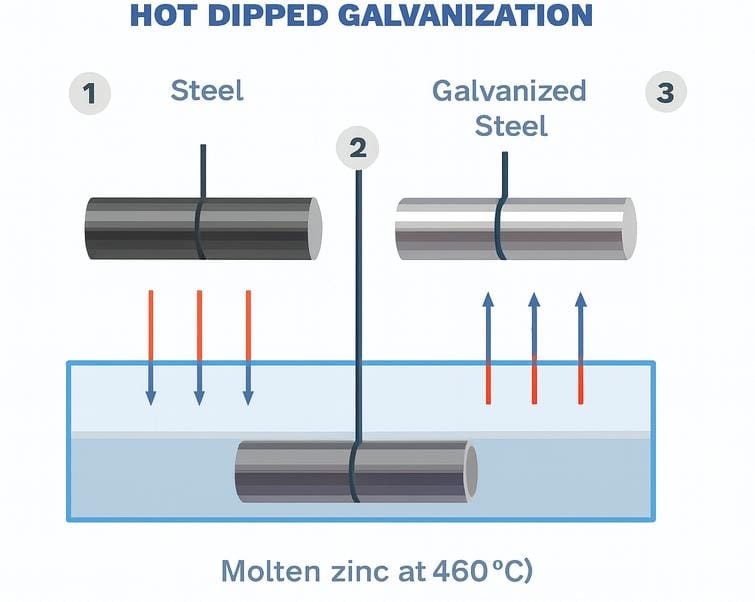

The most common production method is Hot-Dip Galvanizing (HDG). The steel is thoroughly cleaned and submerged into molten zinc at approximately 450°C. During dipping, the coating metallurgically bonds with the steel — creating strong zinc-iron alloy layers beneath a pure zinc topcoat.

As GI steel ages, the outer zinc slowly transforms into zinc carbonate, forming a stable, self-protecting patina that significantly extends the product’s lifespan in outdoor environments.

Even if the coating is scratched, adjacent zinc continues to corrode preferentially, protecting exposed steel surfaces. This unique self-healing ability is what makes GI a trusted solution in the construction and infrastructure sectors.

Like all coatings, performance depends on coating thickness and environment — high temperatures or aggressive chemicals may require careful specification and maintenance.

Common uses include roofing sheets, wall claddings, roll-formed channels, fencing structures, cable trays, guardrails and a wide range of utilities and accessories.

ZAM is an advanced metallic coating combining zinc, aluminum, and magnesium. It is engineered as a next-generation evolution of traditional galvanization, delivering superior corrosion resistance and longer coating life. In the coating, zinc supplies sacrificial protection, aluminum builds a durable physical barrier, and magnesium promotes stable corrosion products that slow degradation.

Typical commercial ZAM compositions are roughly 90–93% Zn, 5–8% Al, and 1–3% Mg. Even small percentages of magnesium noticeably improve performance in chloride-rich or coastal environments by forming protective magnesium-based corrosion films at damaged spots.

ZAM is applied by a continuous hot-dip process similar to HDG, but with a Zn-Al-Mg bath and precise air-knife control. The result is a tough, self-healing coating that often outperforms GI and Aluzinc in long-term exposure tests.

Recommended uses include coastal roofing, architectural cladding, solar module frames, cable trays, agricultural structures, and outdoor fixtures where long life and low maintenance are priorities.

Limitations: ZAM requires attention to welding procedures (due to Mg), and performance can be reduced in very alkaline chemistries — specs should be checked with the mill for specialised applications.

| Feature | GI (Hot-Dip) | ZAM (Zn-Al-Mg) |

|---|---|---|

| Coating Type | Thick Zn & Zn-Fe alloy layers | Zn-Al-Mg alloy topcoat |

| Typical Thickness | 20–120+ µm (depends on spec) | 8–30 µm (mill dependent) |

| Salt Spray / Coastal Performance | Good | Excellent (often 5–10× longer in salt tests) |

| Formability / Paintability | Moderate (alloy layers) | Very good — excellent paint adhesion |

| Self-Healing / Sacrificial Protection | Strong | Strong + improved barrier (Mg helps) |

| Typical Applications | Roofing, fencing, barriers, outdoor structures | Roofing, cladding, solar frames, coastal structures |

| Limitations | Variable coating thickness; heat sensitivity | Sensitivity to strong alkali; welding care needed |

Klang Valley | Delivery Available | Self-Collect Options

WhatsApp UsAll images, diagrams, and examples used on this page are for illustrative and reference purposes only. Copyright belongs to their respective owners. If any materials need to be credited or removed, please contact us.