Hot Rolled (HR) Steel

Hot rolled steel is produced by heating slabs or billets above their recrystallization temperature (typically 900–1100°C) and then passing them through a series of reducing rollers. Because the steel is shaped at such high temperatures, it remains soft and malleable, allowing it to be formed into large structural shapes with ease. The high-temperature process creates a rough mill scale surface and looser dimensional tolerances compared to cold rolled steel.

As the steel cools naturally at room temperature after rolling, internal stresses remain low, giving HR steel good weldability and making it suitable for applications where surface appearance is not critical. Its low production cost and versatility make it widely used in infrastructure, automotive frames, pipes, general fabrication, and heavy machinery.

Limitations include lower dimensional accuracy and a rougher finish, which may require further processing such as pickling, cold reduction, or coating to improve appearance or performance. Despite this, HR steel is a cost-effective choice for heavy-duty applications where precision and surface finish are secondary concerns.

Cold Rolled (CR) Steel

CR Surface

HR Surface

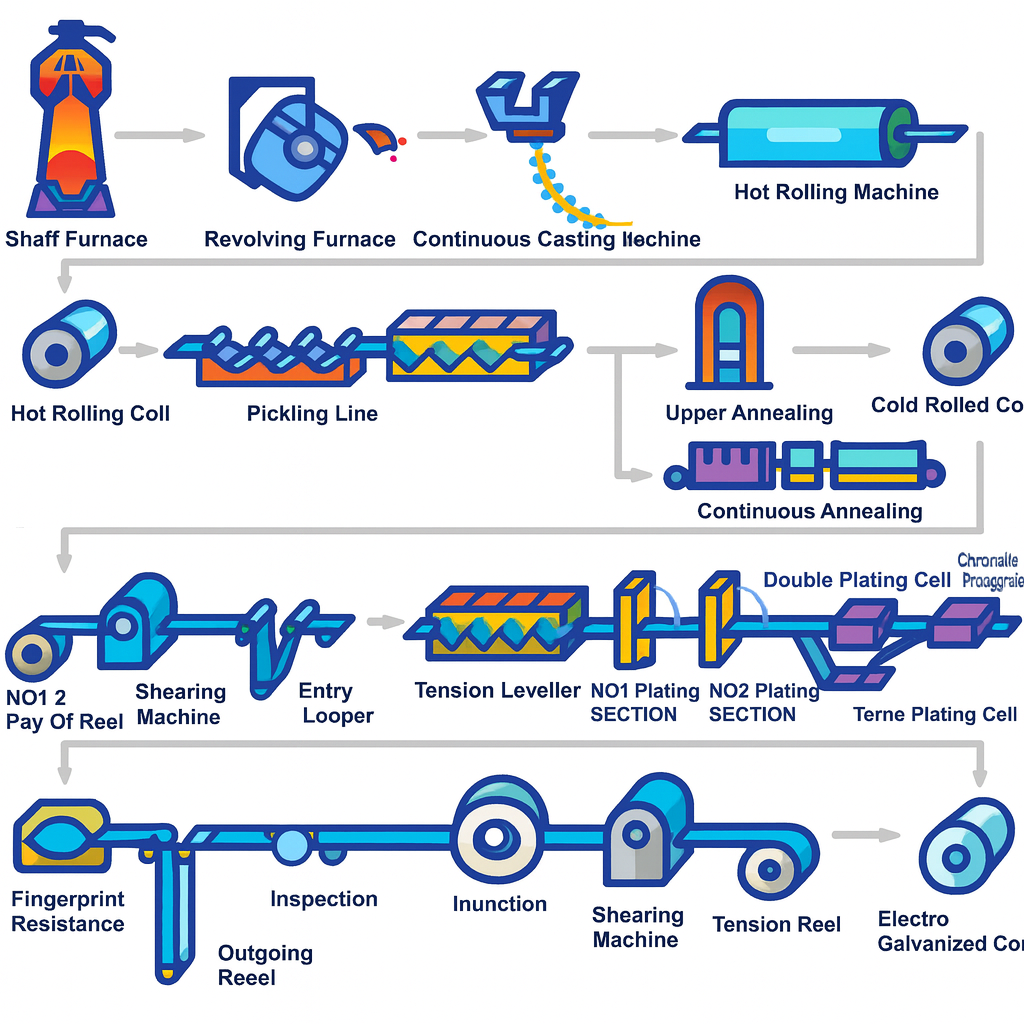

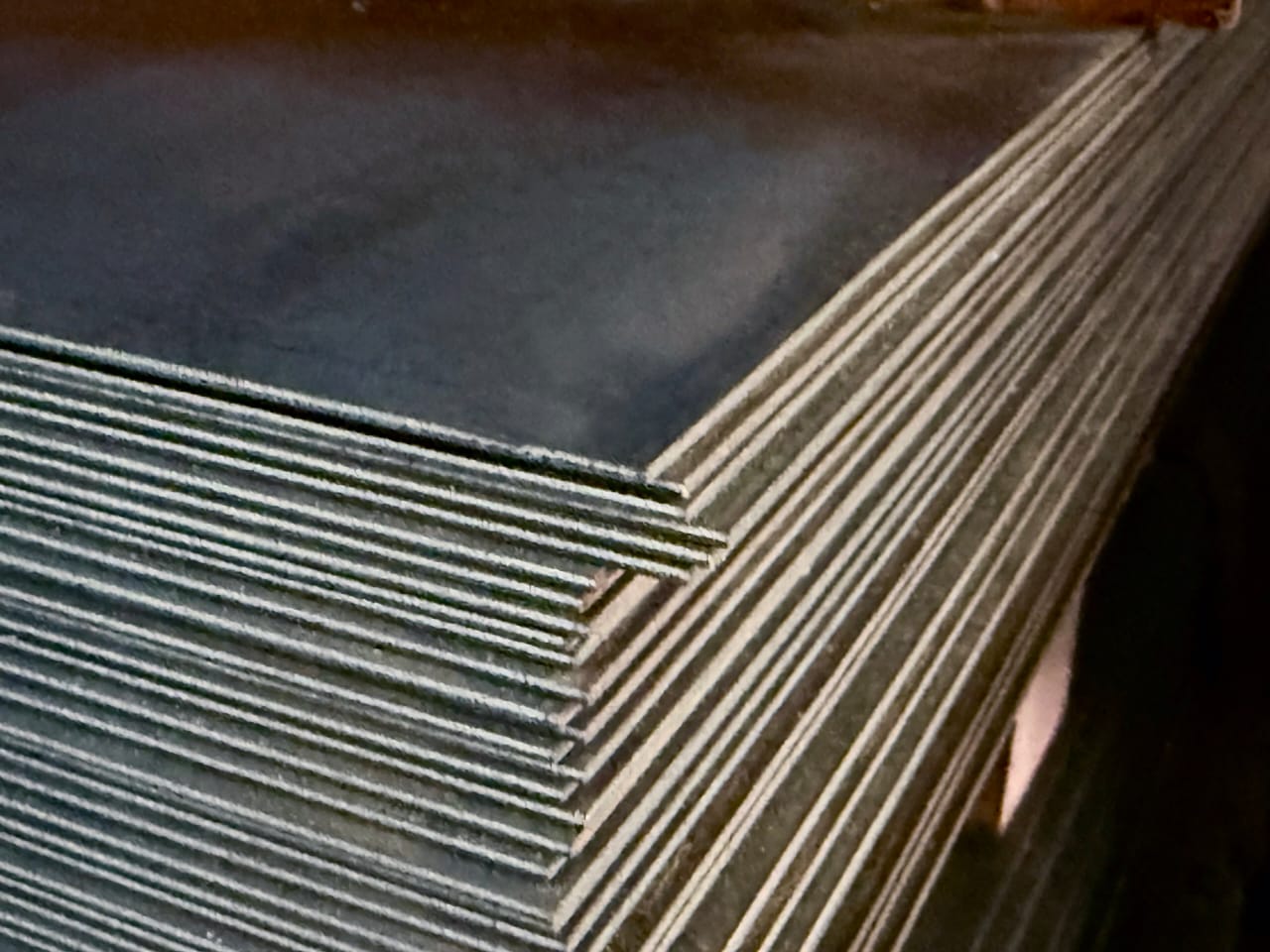

Cold rolled steel begins as hot rolled coil which is pickled to remove mill scale, then passed through rollers at room temperature for further reduction. This improves surface finish, mechanical strength, dimensional accuracy, and uniformity. The material becomes strain-hardened, achieving higher yield strength and tighter thickness tolerances than HR steel.

CR steel offers a smooth, clean, and reflective surface, making it ideal for high-precision and aesthetic applications. It is commonly used in home appliances, automotive body panels, electrical panels, office furniture, and as a base material for downstream coatings including electro-galvanizing, galvanneal, and tinplate.

Because cold forming adds internal stresses, annealing may be required to improve formability. Although CR steel offers superior appearance and performance, the additional processing costs make it best suited for applications where surface finish and tight tolerances are essential.

MS Metal Supplies Sdn Bhd

MS Metal Supplies Sdn Bhd